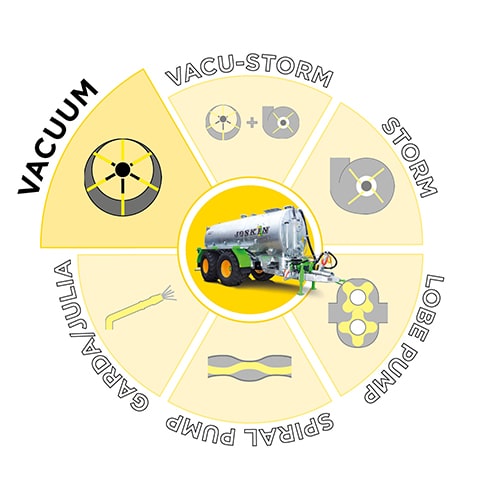

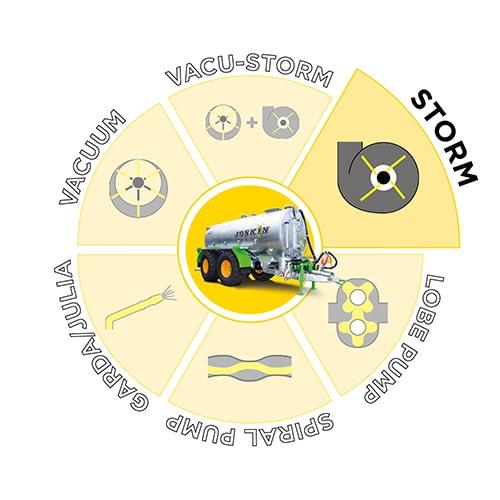

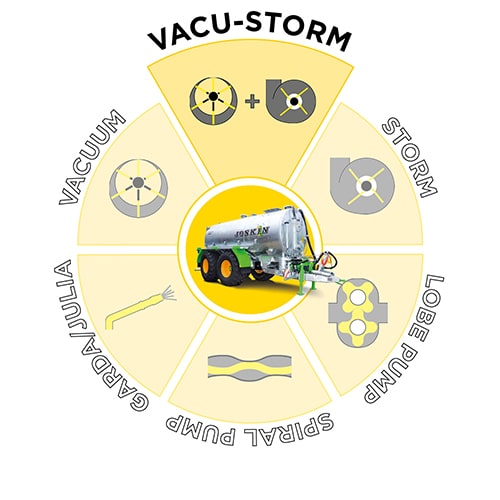

How do i choose the right type of pump?

JOSKIN offers several categories of pumps designed for different uses and conditions. The following pages will guide the user in order to make the best possible choice according to his/her needs.

Once the pump has been chosen, it is essential to determine the capacity and the number of axles of the tanker as well as the spreading implement adapted to the use that will be made of it. In terms of slurry spreading, JOSKIN offers a wide and complete range to meet the demands of all types of farmers: from small farms to agricultural businesses and biogas plants.

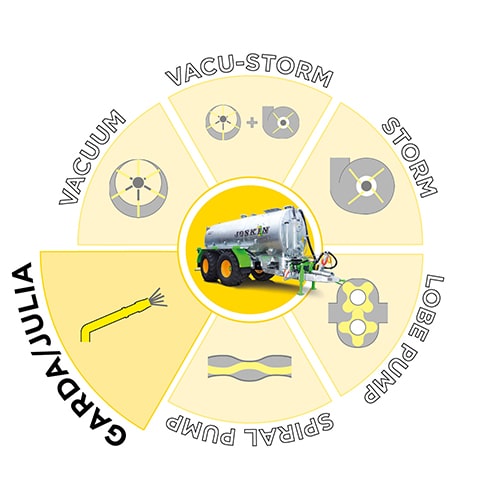

- Vacuum

- Centrifugal pump (Storm)

- Vacu-Storm

- Lobes

- Spiral Pump

- Garda/Julia

Vacuum

- Working principle

- Advantages

- Features

Working principle

Advantages

- Very good price/efficiency ratio

- Low wear as there is no contact between the slurry and the pump

- Low maintenance costs

- User-friendly system

- World's most widespread system

- Suitable for many pumping situations

Right Flow

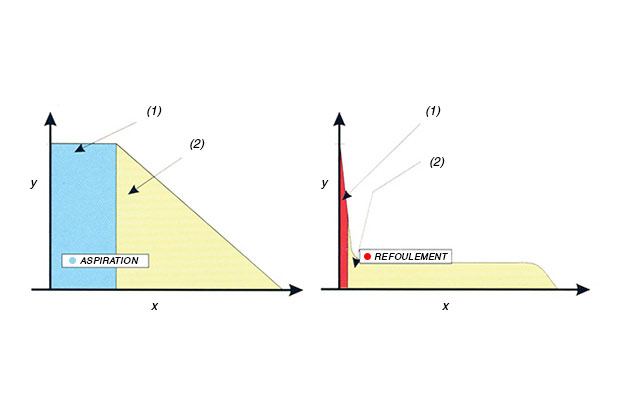

Choosing the capacity (air flow) of your vacuum pump is an important step in the configuration of your slurry tanker. In the suction phase, it is interesting that the vacuum takes place within one minute. A pump with a flow rate per minute equal to the total capacity of the tank is therefore logically the first choice. For example, a pump that can suck up 10,000 l of air/minute will not only create a vacuum in your 10,000 l tank in just 1 minute, but will also maintain this vacuum during the entire filling process. If the flow rate was 5,000 l/min, this operation would have taken at least twice the time. In the spreading phase, i.e. the emptying phase, the pump just has to provide enough air inside the tank to empty it evenly. Choosing a too large pump means wasting tractor traction power, with a risk of premature wear. The vacuum level remains the same regardless of the pump chosen.

lightblueSuction

x) Filling time

y) Pump capacity

1) Time to "create the vacuum”

2) Maintain the vacuum

redDischarge

x) Spreading time

y) Pump capacity

1) Time to pressurize the tank

2) Maintain the compression ratio

Direct Connection or Speed-Increasing Gearbox

The 1,000 rpm version (direct connection) is usually more interesting, as it allows, in combination with the tractor P.T.O. rpm selector, to adjust the pump capacity to the required spreading flow. In addition, the pump running at a lower rpm saves engine power, which is beneficial for the tractor traction during spreading.

Cooling of Vacuum Pumps

Cooling the pump is a major challenge for manufacturers. In addition to a traditional air flow, pumps are designed with fins for a conductive cooling. There is a slightly more efficient system, called "Ballast Port", which is also a low-cost solution: a continuous injection of fresh air into the pump body cools it down and allows it to work at 60% vacuum continuously. It is used on most of the models manufactured by “JUROP”.

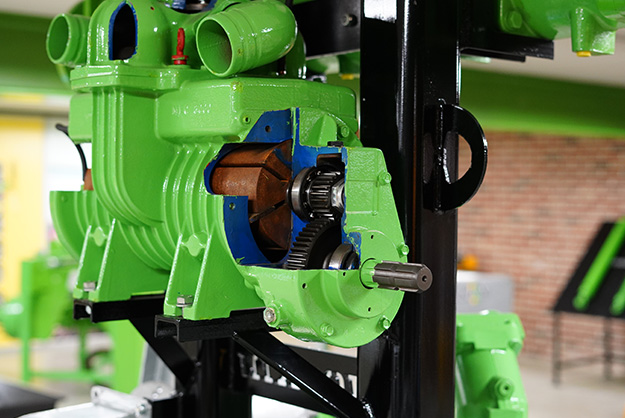

Vacuum Pumps with Vanes

JOSKIN mainly installs mobile vane pumps driven by an eccentric rotor that always rotates in the same direction: the air flow is directed by a deflector valve to either pump or spread slurry. They all achieve an equivalent vacuum, regardless of the model or capacity. It is therefore the range air transfer capacity of the pump that should be taken into account. JOSKIN offers a from 4,000 to 15,500 l/min. The main models are the MEC from Battioni & Pagani and the PN(E/R) from JUROP. They all have at least one forced drip lubrication that can be adjusted manually or automatically at the factory. The lubrication takes place both during the suction and the discharge phase. The JOSKIN Vacuumoil is specially designed for the pump vanes: a 5 l can is supplied with each slurry tanker equipped with a vacuum pump with vanes.

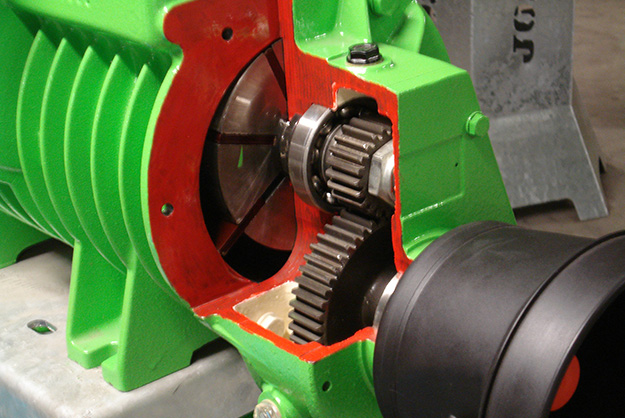

Vacuum Pumps with Lobes

The 3 JUROP DL vacuum pumps offer large capacities: 17,600, 21,600 and 25,000 l air/min. Coming from the industrial sector, and more specifically from the hydrocleaners, they have two rotors with lobes instead of vanes. The absence of contact between the moving parts allows a lubrication-free operation. It is cooled by air injection. The advantages of this type of pump are its large capacity and small size. Moreover, the JUROP DL is not subject to wear and tear or pollutant emissions. As standard, it is equipped with suction and discharge silencers. JOSKIN also equips its DL pumps with a temperature alarm and filters to prevent foreign bodies from damaging the lobes.

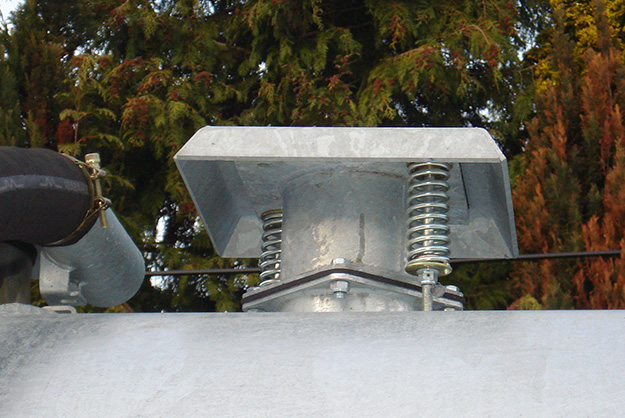

Pressure Relief Valve

All JOSKIN tankers with a vacuum pump are fitted with a tank overpressure security set at + 1 bar. When the pressure inside the tank exceeds this value, the springs compress, the top lid of the valve lifts and the pressure drops rapidly. Once the pressure is reduced to below + 1 bar, the lid returns to its initial position thanks to the return springs.

Ball Safety Device

Based on a float system, the ball safety device (or overflow valve) prevents the slurry from following the same path as the air. When the tank is filled, the ball blocks the air outlet and prevents the slurry from flowing into the pump.

Syphon

The self-cleaning syphon (30 or 60 l) serves as an additional safety device between the tank and the pump. It is designed to empty automatically when air is forced back into the tank. For an easy maintenance, self-cleaning syphons are fitted with a cleaning plug.

Ecopump

This ecological and economical system offers 3 advantages: it collects the used oil coming out of the pump, reduces the noise pollution considerably and sucks in the air from above to prevent it from becoming dusty. This accessory considerably increases the lifespan of the pump.

JOSKIN Special Valve

The high-capacity JOSKIN pressure relief valve (Ø 150 mm) allows the air to be quickly evacuated and prevents a premature heating of the pump. It also gives the possibility to adjust the spreading rate by acting on the internal pressure of the tank.

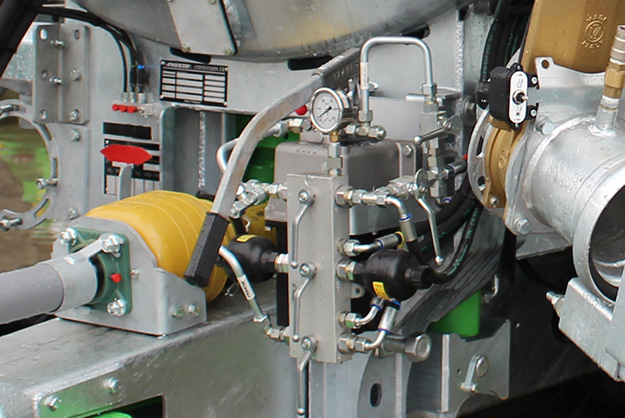

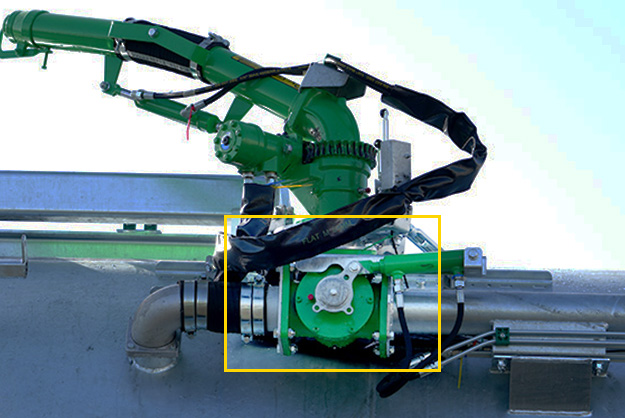

Pump Change-Over

A vacuum pump is equipped with either a mechanical or hydraulic change-over, which allows you to choose between "spreading" and "suction". The hydraulic control is essential when using a filling device such as a JUMBO arm, a dorsal boom, etc. The change-over is operated from the tractor cab to anticipate pumping or spreading.

Centrifugal pump (Storm)

- Working principle

- Advantages

- Features

Working principle

Advantages

- Very high and linear slurry flow

- Limited wear and low maintenance costs

- Possibility to discharge/spread thicker slurry

- Output pressure of over 1 bar for a good distribution on a large working width

- Stone trap protecting the pump from foreign materials

- Possibility to mix in closed circuit

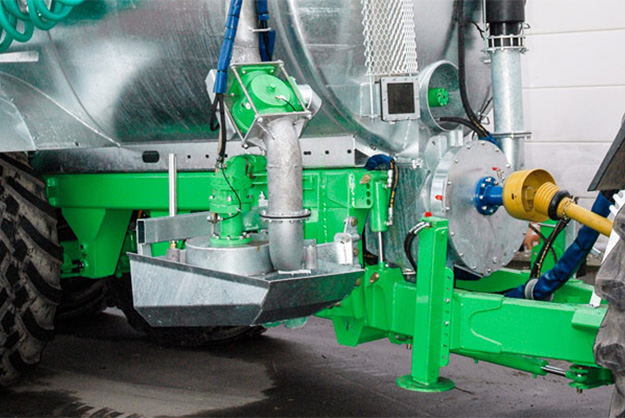

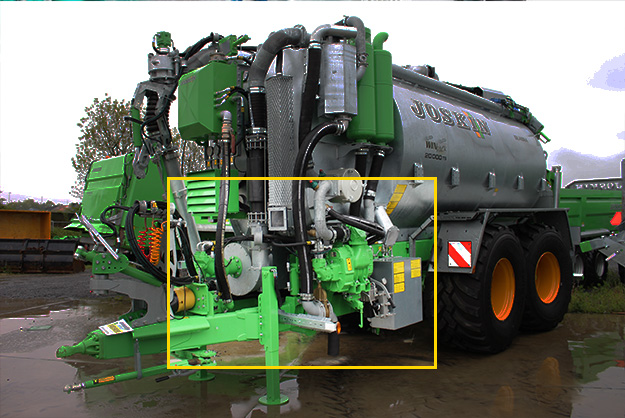

Dual Storm

The DUAL-STORM concept is based on the combination of two centrifugal pumps: one fitted at the end of the dorsal boom for filling and the other at the front of the tank for discharging. Its main feature is its high flow rate of around 10,000 l/min depending on the type of slurry. Its three-blade propeller requires little maintenance compared to other high-flow volumetric pumps of the "lobe" or "spiral" type, since it is less sensitive to the passage of foreign bodies. As with all volumetric systems, the centrifugal pump ensures a better filling of the tank, while avoiding the creation of foam (which is discharged into the pit through the overflow pipe). The DUAL-STORM concept is available with a mechanical or hydraulic (Power-Pack) drive, both of which are supplied as standard with a flow meter.

Dual Storm + Vacuum

The DUAL-STORM provides a great flexibility of use and a power appropriate to the desired flow rate. As this device is not self-priming, it is necessary to use a small vacuum pump to vacuum the boom if you want to suck on a funnel. In this case, a hydraulically driven vacuum pump (Battioni & Pagani MEC 5000H) is placed on the side of the tanker. It is managed by an ISOBUS solution and solenoid valves.

Power Pack

The JOSKIN Power Pack completes the DUAL-STORM assembly: in this case, the motors of both pumps are driven hydraulically via a hydraulic installation (160 l/min at 280 bar). A double-acting industrial valve isolates the tank from the centrifugal pump body. As standard, the DPA proportional flow system controls the STORM pump rpm.

Vacu-Storm

- Working principle

- Advantages

Working principle

Advantages

- Flexible: suitable for all pumping situations

- Stone trap protecting the pump from foreign materials

- Possibility to mix the slurry in closed circuit

- Efficient: possibility to spread over large widths

- High and constant slurry flow

- Easy and low-cost maintenance

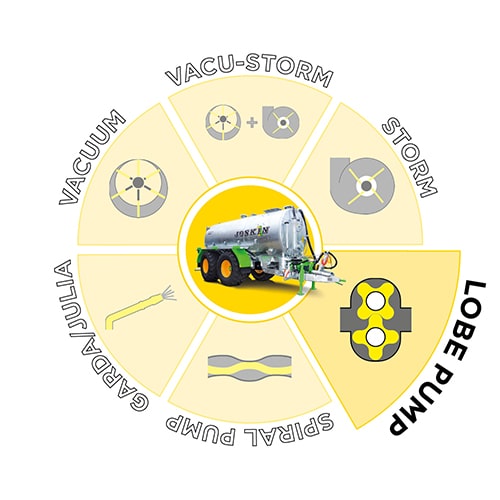

Lobes

- Working principle

- Advantages

- Features

Working principle

Advantages

- High suction/discharge flow

- Possibility to suck up thick slurry

- Compatibility with long suction hose lengths

- High suction depths possible

- Compact pump

Side Fitting

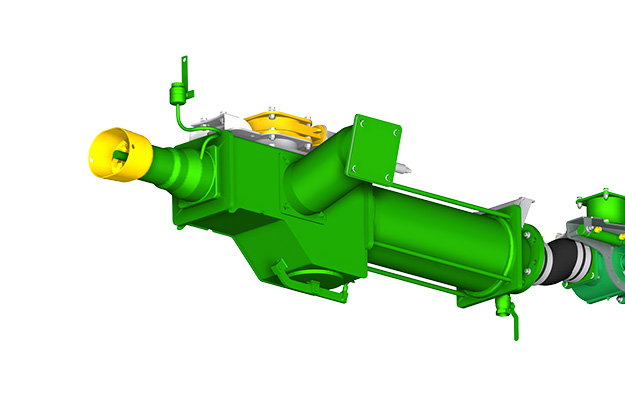

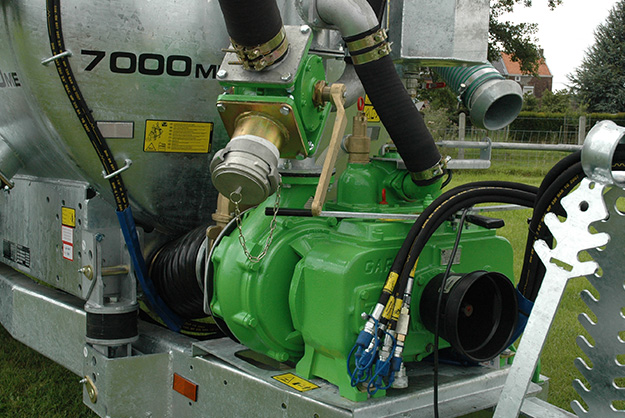

The Vogelsang lobe pumps offered by JOSKIN are all equipped with HiFlo® lobes that guarantee a perfectly linear flow. This means that they are not subject to vibration, thereby extending the lifespan of the moving parts. This unique design limits cavitation, allows higher rotation speeds, and therefore higher flow rates, for the same pump size. Lobe wear and turbulence at the inlet are greatly reduced. JOSKIN fits the lobe pumps on the side of the tankers so that they are easily accessible for maintenance. This assembly includes a PTO drive and an angle transmission gearbox. As an option, the drive can also be powered by a hydraulic motor, for an easier and more precise adjustment of the flow rate.

Chopper

In order to protect the volumetric pump as much as possible against foreign bodies or to avoid blockages due to heavy slurry, JOSKIN has developed the "Rotation-Cut" chopper. It is placed before the pump inlet to filter the slurry. This large-volume chopper is equipped with a drain valve: when you arrive at the field, you can open it from the driver's seat to remove any foreign bodies (stones, etc.) it could contain.

Automatic

Unlike vacuum pumps, the slurry goes through the volumetric pumps and the flow rate mentioned here is the amount of liquid per minute. When used on slurry tankers, there could theoretically be an overflow. In order to avoid such a situation, an automatic filling stop system can be fitted. In this case, a signal from the float gauge gives the filling status and changes the position of the valves from "full" to "mixing in closed circuit". The pump then no longer sucks in slurry and does a mixing job.

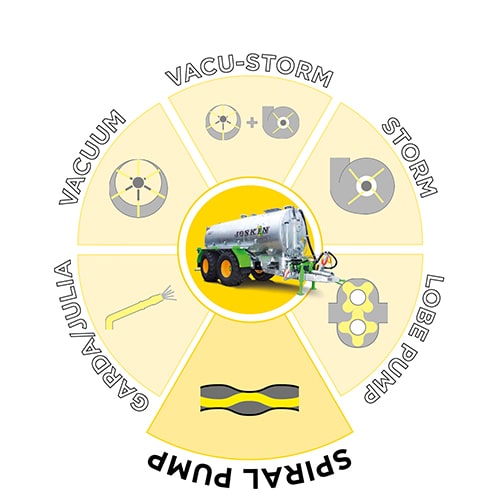

Spiral Pump

- Working principle

- Advantages

- Features

Working principle

Advantages

- High suction/discharge speed

- Possibility to suck up thick slurry

- Compatibility with long suction hose lengths

- High suction depths possible

- Standard equipment for mixing in closed circuit and transfer from one pit to another one

- Easy and low-cost maintenance

Stone Trap

The spiral pumps on the JOSKIN slurry tankers are equipped with protection systems in the form of external or internal stone traps to prevent them from wearing out too quickly if they come into contact with foreign bodies. Regardless of their configuration, these devices are always equipped with a system to quickly remove stones and foreign bodies.

Automatic Stop

Unlike vacuum pumps, the slurry goes through the volumetric pumps and the flow rate mentioned here is the amount of liquid per minute. When used on slurry tankers, there could theoretically be an overflow. In order to avoid such a situation, an automatic filling stop system can be fitted. In this case, a signal from the float gauge gives the filling status and changes the position of the valves from "full" to "mixing in closed circuit". The pump then no longer sucks in slurry and does a mixing job.

Garda/Julia

- Working principle

- Advantages

- Features

Working principle

Advantages

- Versatile (centrifugal or vacuum pump)

- Centrifugal pump: high-flow discharge for spreading gun (slurry and irrigation)

- Vacuum pump: traditional spreading

- Ideal for irrigation works

- Ideal for steep areas with difficult access

- Low maintenance costs

Spreading Gun

With a spreading gun, you can reach an area where the tractor cannot go, such as in the mountains, on hills or beyond some hedges. The centrifugal pump of the GARDA/JULIA system can eject the slurry up to a distance of about 40 metres, depending on the viscosity of the liquid being spread. Water irrigation works, for instance in arboriculture, are also possible.

Quick Coupling

Thanks to a quick coupling at the outlet of the centrifugal pump and a manual 3-way valve with return to the tank, it is easy to connect an umbilical system and to adjust the flow rate.

Mixing in Closed Circuit

The possibility of mixing in a closed circuit is very useful with a relatively heavy slurry. The liquid propelled by the centrifugal pump is reinjected into the tank. This mixing method is very effective to get a homogeneous mixture quickly and easily.

Vacuum

Vacuum Pumping System

The vacuum system creates an atmospheric pressure difference in order to fill or empty the tanker. By creating a vacuum (depression) in the tank, slurry can be sucked. When spreading, the principle is reverse: the tank is pressurized by the pump, which allows to expel the slurry.

- Price/efficiency ratio

- Limited wear (no slurry in the pump)

- Low maintenance costs

- user-friendly system

greenSuction/filling

blueAir intake in spreading phase

lightblueAir intake in suction phase

orangeTowards spreading implements

- Rotary pump with eccentric rotor and forced lubrication system

- The blades slide into the seatings of the moving rotor and are kept in contact with the pump housing under the action of the centrifugal power.

- The moving blades ensure an air displacement creating a depression at the pump inlet and an overpressure at the outlet. The pump change-over allows to direct these flows, suck or spread.

- Lobe pump with higher spreading capacity

- Since there is no friction between the lobes, overheating and wear of the components are limited

- It is an eco-friendly system since there is no lubrication system

- The moving lobes ensure an air displacement creating a depression at the pump inlet and an overpressure at the outlet. The pump change-over allows to direct these flows, suck or spread.

Garda

GARDA system

The GARDA/JULIA system with 100% mechanical drive combines a Garda or Julia centrifugal pump with a vacuum pump (respectively Battioni & Pagani or Jurop). A pump change-over allows to choose the desired pump type. Standard delivered with a high-flow spreading gun, it is however still possible to feed a rear spreading implement or an umbilical system.

- Emptying through spreading gun to spread on very uneven grounds while the tanker remains on a flat area.

- Irrigation works possible

greenSuction/filling

blueAir intake in spreading phase

lightblueAir intake in suction phase

Lobe pumps

Pumping system with lobe pump

Lobe pumps are volumetric pumps. This system uses the mechanical action of two lobe rotors. As they turn, they create a vacuum on the suction side, which is determined by the rotation direction, which allows to attract the slurry into the pump housing. Then, slurry is driven by the lobes, goes along the rotor wall and is spread.

These pumps do not take much place although they have a relatively high capacity. Their sucking principle ensures them a maximum stability and eliminates almost all vibrations. Furthermore, they are all standard fitted with an automatic stop system and wear rings. We propose pumps of the Vogelsangbrand.

- Higher speed when filling/emptying (depending on the pump flow)

- Better filling level, especially with thick slurry and/or very deep pits

- Possibility to pump up to 3.5 m deep

- Standard equipment for mixing and transfer from pit to pit

- Perfectly linear flow

- High outlet pressure, for a good distribution even with large working widths

greenSuction/filling

blueAir intake in spreading phase

lightblueAir intake in suction phase

orangeTowards spreading implements

Storm

STORM Centrifugal Pumping System

The STORM system sends the slurry out of the pump thanks to the centrifugal power created by the rotation of a screw around an eccentric pump housing. The centrifugal pumping system certainly reaches the highest flows (up to 10,000 l/min).

Storm pumps only work when emptying. The tank is therefore filled by the gravitational force through an upper hydraulic access.

- Very high and linear slurry flow

- Limited wear and low maintenance costs

- Possibility to pump thick slurries

- Low risk of cavitation

- Pressure at the exit above 1 bar for a good distribution on high working width

greenSuction/filling

blueAir intake in spreading phase

orangeReturn to the tanker when the rear valve is closed

Spiral

Pumping System with Spiral Pump

The spiral pump system makes use of a rotor with screw to suck and spread slurry. The rotation of the screw inside the stator then creates a series of hermetic chambers that move along the suction/discharge axis, resulting into suction and discharge.

- Higher speed when filling/emptying (according to pump flow)

- Possibility to pump thick slurries

- Compatible with very long pipes (pumping or spreading tool)

- Possibility to pump up to 3.5 m deep

- standard equipment for mixing and transfer from pit to pit

- Pressure at the exit above 1 bar for a good distribution on high working width

greenSuction/filling

blueAir intake in spreading phase

lightblueAir intake in suction phase

orangeTowards spreading implements

Vacu-Storm

VACU-STORM system

The Vacu-Storm pumping system includes the advantages of the Vacuum system in filling phase and the centrifugal one during the emptying phase. An optimal solution for the users looking for an absolute flexibility.

✓ Performant : possibility to spread on large widths

✓ Simple mounting and perfectly integrated on the machine

✓ Efficient feeding of the centrifugal pump

✓ High and constant slurry flow

✓ Easy maintenance

greenSuction/filling

blueAir intake in spreading phase

lightblueAir intake in suction phase

orangeTowards spreading implements